On December 2, 2023, the U.S. Environmental Protection Agency (EPA) issued its final ruling on new standards outlined in 40 CFR part 60, subparts B and Ba. The rule established a zero-emissions performance standard for new and existing process controllers, or pneumatic controllers, to reduce the volume of greenhouse gas (GHG) emissions. While this change would reduce the volume of methane (CH4) or volatile organic compounds (VOCs) released into the atmosphere, veterans of the oil and gas industry raised a poignant concern ahead of the final ruling. New controllers would be designed to meet the zero-emissions standard, but the industry was saturated with controllers that fell short of new standards. Furthermore, retrofitting these devices to meet the new standards would require operators to integrate elements like generators and fired equipment, which are emitters in their own rights. This left many with the question: how does one possibly achieve a zero-emission standard by using GHG-emitting equipment?

The EPA’s Expectations Explained

Put plainly, it is impossible to reach a rate of zero-emissions through the use of emitting equipment; however, the EPA recognizes industry inaction would cause far greater environmental harm. Of the common GHGs, the latest EPA ruling identifies methane and VOCs as the most pressing targets for mitigation efforts.

Although fired equipment and generators may release chemicals like CO2 and NOx (N2O & NO2), yet their combined contribution to global warming remains considerably outweighed by that of VOCs and methane. According to a comparative analysis conducted by the EPA, the total reduction of CO2 eq. (equivalent) – meaning methane and/or VOCs— through the use of CO2 emitting technology like fired equipment and/or natural gas driven generators, still results in a net CO2 eq. reduction upwards of 95%. In their findings, the EPA acknowledged the existence of other routing options which would allow facilities of all sizes to achieve a true zero-emissions status of a 100% reduction.

Cordova Methane Control’s patented pneumatic vent gas capture and utilization system helps operators achieve zero-emissions compliance with their existing equipment. The system routes exhaust gases from a level controller/dump valve, high/low controller/dump valve or pneumatic temperature controller to VentHawk, and it directs the gas to the pilot line of the separator or other equipment’s burner system for clean utilization. The VentHawk and VentHawk CH4 have been reviewed and accepted by the states of Colorado and New Mexico as an economical option for producers to implement to attain venting compliance. Other states are currently in the process of reviewing the technology as well.

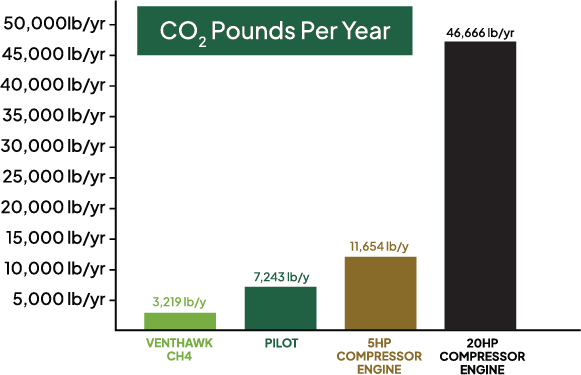

As indicated in the chart above implementation of compressors vs. routing vent gas to a pilot via the VentHawk results in significant CO2 reduction and significant cost savings. For locations where electricity is not available, the VentHawk CH4 unit results in even fewer CO2 emissions and even greater savings.

As operators begin the implementation process to meet both EPA and Inflation Reduction Act requirements, secondary CO2 emissions will be at the forefront of the evaluation process. Operators should take heed of the EPA’s stance addressing and acknowledging secondary CO2 emissions.

For additional information about VentHawk or VentHawk CH4 or to schedule a demo, please contact Cordova sales team member, Tim Westmoreland.

Download Our Guide to New Process Controllers (Standards of Performance for New, Reconstructed, and Modified Sources and Emissions Guidelines for Existing Sources)